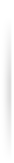

The fresh fish is brought to the factory in iced condition. The icing is done depending upon the transporting time. The raw material is taken through the conveyors from the fish tanks through a metal detector (to catch the metal items) to the “Cookers” which makes use of indirect steam for cooking the fish in a temperature of 80-85°C for about 25-30min. The cooked fish is later pressed in “Screw Press” to separate Fish liquor (Press Liquor) and Fish solids (Press cakes). The fish liquor hereby termed as “Stick water” is collected in a stick water tank for further oil separation.

The press cake having 40-45% moisture is forwarded to the “Steam Drier”, so as to reduce the moisture to about 9-10% with the help of indirect steam at a temperature of 80-90°C inside the drier. The Dried fish meal is forwarded into the “Pulverizer” for converting into fine particle size. The fish meal is sieved in a “Siever” to remove the foreign particles/ bones/ scales and only the fine powdered fish meal is collected and passed through a cooler maintaining the output fish meal temperature at 27-30°C. In an aseptic environment the fish meal is packed directly into an inner coated polypropylene bag of 50kg capacity. The fish meal thus produced is stored in a well maintained Godown.

The shelf life of the fish meal is increased by adding antioxidant (Ethoxiquin) in recommended dosage.

The Press liquor from the stick water tank is fed into the “Super Decanters” to remove the solids from the stick water. The liquid of stick water that is free from solids is fed into the “Super Centrifuges” or “Three Phase Centrifuges” for separation of water and oil from stick water. The oil that is produced is the “centrifuged fish oil” which is stored in Oil storage tanks.